It took more than 2 years for the US to train their crack airborne Para troops for WWII.

I however want more for the up coming August offensive…

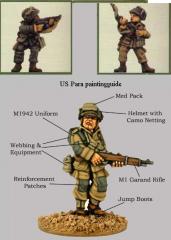

So I have done some research on painting US WWII airborne and apparently they had two uniforms..the 1942 and the1943.

The 1943 is defiantly more olive drab or dark green and I decided not to go for this but adopted the 1942 with the very light tan colored uniform.

Unfortunately there is no decent color from Tamiya paints that represents the uniform. So I decided to wing -it with colors and expect some variation any way in the final shade.

I have decided to use dunkelgelb or sand yellow… I will use some tinted shades.. much like inks to get the desired effect.

Here are some nice photos of what is desired

This shows the 1943 uniform in comparison… which is very green.

This beautiful figure is the basis of what I am trying to achieve.

On to business.

I have decided to use airbrush and washes/inks to make speed with this job. The desired finish is table top standard.. not display.

Because of the overall color scheme this is much more achievable as the trousers and blouse are all the same color.

Step one:

I have my figures glued to card strip and metal primed already. I just take the trusty snips and cut them to strips of troops.

Cut

Step two:

Assemble my work space… here I have my airbrush, paints, pots and all the other necessaries to air brush.

Step three:

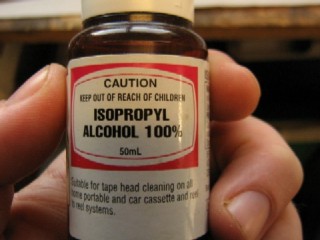

I have mixed Tamiya XF-60 or dunkelgelb with a considerable amount of; Alcohol thinner 100% (ideally 90% works better), Liquifying agent, water, and a tiny amount of retardant.

The mix is very watery. If sprayed at too close a distance it will bead like water on the model. at the right distance it mists the model as a first coat. Because it has so much alcohol ad water in it, it dries real fast. Which means a second coat in about three of four minutes when your on a second cup of paint adheres beautifully.

And that’s is it so far… here are finished results today.

Now I will be brush painting next.